How to Make Ceramic at Home Without a Kiln:

Most sources on the internet say you can’t bisque fire pottery in a wood stove. Sure, it’s possible: Fire pottery in a wood stove is like primitive pit firing in a metal box, the stove itself won’t get hot enough, but in the fire, between the logs, it’s more than hot enough.

How To Fire Pottery In a Wood Stove:

How To Fire Pottery In a Wood Stove:

Though you can fire pottery in your house fireplace, there exist better low-cost alternatives. This one is my favorite:

https://www.woodfireceramic.com/coil-building-the-clay-kiln/

How to fire clay to ceramic in an ordinary wood stove:

First, a word about safety: I’m not qualified to give fire-technical safety advice. I don’t know your woodstove or your pipe. The only thing I say here on this page is that this is safe in my stove; I fired clay to pottery in my stove more than 100 times.

The bottom line is still: Safety is your own responsibility.

How to Fire Pottery in a Wood Stove- This is How I burn:

The fireplace or woodstove at your home is not the best place to burn pottery or ceramic, but it does work! I have read several places that you don’t reach the temperature you need, and sure, a pottery kiln burns much higher; bisque firing is typically about 1050 ℃, and for glaze-firing, many burn much higher. An ordinary woodstove should not exceed an outside temperature of 2-300 degrees Celsius, and since clay sinter to ceramic at 600 degrees, many think you can’t burn pottery in the woodstove. But the is wrong; the flames are more than hot enough, so between the logs, in the center of the fire, you can reach 6-700 ℃ on your goods. That’s how primitive pit-firing works; just make sure your goods get surrounded by flames. Clay sinters at about 600 degrees, which sounds a lot. But I only fire with one log more than I usually do, and I easily reach + 600 degrees at my ceramic goods. And I only fire for an hour longer than I normally would do when heating my house. Not unlike how I heat my house when I come home to a cold house on a winter day.

The clay body: If you put wet clay in the flames, it will splinter. Water heats up to the boiling point, and the rapidly expanding steam can’t escape the clay body’s tight structure quickly enough, and the goods splinter apart (close the kiln door or use safety goggles). Clay needs to be bone dry before you burn it to clay. If clay feels cold when touched, it contains water; even if it feels dry, it still can. A good practice is to heat up the dry clay on top of the oven the day before burning, so you know it’s dry. Goods on top of my fireplace clay reach 60 – 90 ℃.

How To Fire Pottery In a Wood Stove:

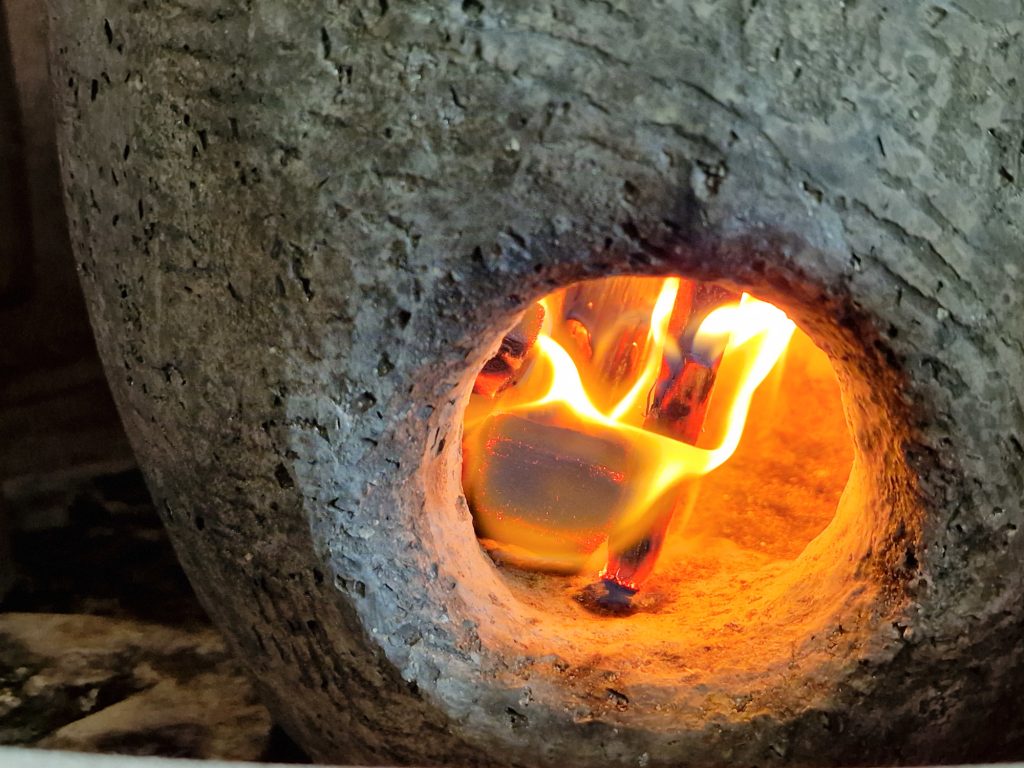

It’s difficult to heat up as slowly in a woodstove like you can in an electrical kiln. So start the fire really slowly with a small flame till you pass 100 ℃. Tough Raku clays and clay with a lot of chamottes are less fragile for quick temperature changes. It’s surprisingly difficult to make a small and steady fire for an hour, that can slowly raise the temperature in the wood stove, where the fire and the clay share the same chamber. For delicate ceramic, a firepot comes to the rescue. The firepot’s reduced fire space, makes it easyer to maintain a small, stable burning flame over a long time. The disadvantage of the firepot is that it occupies valuable space, and it only has a mission in the first 1-2 hours of the burn cycles. Despite its pros and cons, a firepot is priceless when bisque-firing your most valuable goods.

Another way to avoid cracks is to preheat clay in an electric oven slowly til in passed 200 degrees, use a pliers to carry the hot clay over to the wood stove (use glows too).

Maximum temperature: You don’t need a lot of standing wood logs; high flames are not necessary. Lying logs burn slower, but they get the job done; just make sure you have enough embers. Calm flames from two or three logs will reach the desired temperature in a few hours. One thing though; I have a clean-burning wood stove, meaning most of the fire is burned in the stove, and not sent up your pipe as unburned wood gas. Maybe this only works in clean-burning stoves? I don’t know. But I do know that some really old stoves are sending too much heat into the pipe, so check your kiln type.

I get the best result by placing pottery on a wide, flat log and placing a log over the ceramic again. You can hold the maximum temperature for a little while so the pottery get evenly heated (in these low temperatures, it can occur that only one side of the goods turns to ceramic, while the other is still clay). Do not place clay high up in your oven; it is hottest lying close to the bottom, but do not place flat goods directly on the bottom of the oven.

Fire ceramic in a wood stove: I only do bisque firing in my oven, and I can reach the max temperature on the ceramic goods (6-700 ℃) in about 1,5-2,5 hours, let it cool down before the goods can be removed from the oven.

Can you glaze-firing ceramic in a house stove?

A traditional wood stove can reach temperatures where a few melting agents start to flux. Remember, there are safety concerns to be considered, but if a glaze can melt in a campfire, it can also in a wood stove. Read about campfire glazes here:

Read about the lowest of any low-fire flux here:

Remember, it’s easy to make a low-cost DIY homemade ceramic kiln:

Why not build a real pottery kiln in your backyard?

After the clay has cooled down, it is time to find out if the clay really turned into ceramic. Tap the goods with your fingernail, a little ping sound is a good indication it’s ceramic. The color would have changed slightly. But only the water test gives the exact answer: Add some water to your goods, if it starts to color off when you rub your finger against it or starts to feel slippery, it’s still just clay (then dry it one more time and burn it again).

How To Fire Pottery In a Wood Stove:

Fire pottery between the logs in the fireplace is quite similar to pit firing.

If you do like home-firing pottery, also read about the sawdust kiln:

https://www.woodfireceramic.com/the-sawdust-kiln/

Or the Minigama kiln:

https://www.woodfireceramic.com/minigama-coil-building-the-new-mini-kiln/

How To Fire Pottery In a Wood Stove – 2025