My New Low-Fire Ceramic Glazes

Glazes fired between 950 and 1050 degrees Celsius

My New Low-Fire Ceramic Glazes: Here, I make some glazes from scratch. There exists a lot of great low-fired glazes out there developed by ceramists, but here I wanted to make some from scratch myself. I share my experiments as I go. It’s a work in progress, and I’ll be the first to admit I don’t have hundreds of cool glazes at the moment. But things go the right way, and I hope summer/autumn in 2025 gives a lot of new glazes.

Make DIY pottery glazes for wood firing, using raw-materials that cost 1/10 of the price of commercial glazes:

https://www.woodfireceramic.com/diy-pottery-glazes-for-wood-firing/

These glazes do not contain raw materials that make them unhealthy to serve food on, but remember bacteria can grow in cracks in the glaze, or develop on matt and rough surfaces. So foodsafe is about more than just what materials are mixed together in the glaze.

For now, I am experimenting with glazes for sculptural purposes; some can be used for food-wares as-is, but I will test and add more food-safe glazes for pottery as time goes on.

My New Low-Fire Ceramic Glazes With Low-Temperature Ceramic Glaze I mean Cone 05 = 1004℃, that’s my goal. Most of these glazes can handle both a higher span in temperature as well as lower.

Read other articles here:

Exreme Low-Fire ceramic glazes 600°C glaze-fire-ceramics-in-the-campfire/

The most important Raw-material Fluxes for ceramics 9-important-fluxes-for-ceramics

Glazes:

What is a low-temperature ceramic glaze?

TinCan Kiln fast-fire glazes:

My New Low-Fire Ceramic Glazes

What is a low-temperature ceramic glaze?

All glazes on this page are low-temperature / low-fire glazes: They are tested and developed for a short firing range (3-12 hours) and burned up to Cone 05 (Cone 05 = 1004℃). The glazes are all tested for wood-firing, but temperature vise there is no difference between an electric kiln, so yes these glazes should work in many types of kilns.

My New Low-Fire Ceramic Glazes – It’s always handy to understand the basics of glazes. Understand the difference between the melting agent (the flux), the glass-former, the stabilizer, and the fun part; the colors. It is core know-how, and handy when you have the “perfect” glaze, but it needs just a little adjustment.

Cones and temperatures i Celsius:

The low-fire glaze scale:

Cone 013 = 807 ℃

Cone 012 = 843℃

Cone 011 = 857℃

Cone 010 = 891℃

Cone 09 = 907℃

Cone 08 = 922℃

Cone 07 = 962℃

Cone 06 = 981℃

Cone 05 = 1004℃

Cone 04 = 1021℃

Cone 03 = 1046℃

Cone 02 = 1071℃

Cone 01 = 1078℃

Cone 1 = 1109℃

Finally a new Low-Fire Glazes book for sale! I am so looking forward to reading it! Let’s hope it lives up to the expectations, and so far it does! But it relies heavily on frits for melting agents, that’s not my thing … but it’s a good read so go and buy it, it has a lot of knowledge.

(this is not an affiliate link)

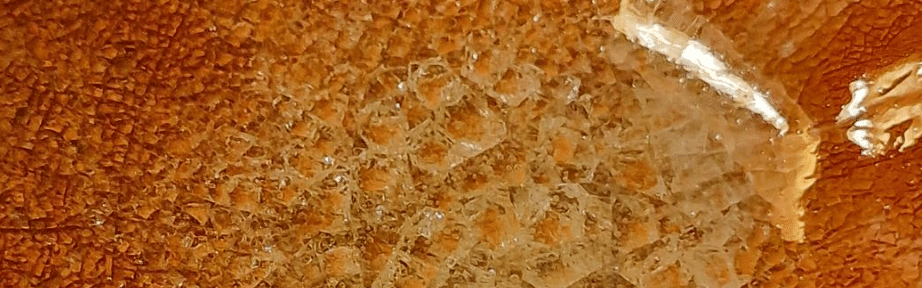

My High Fire glazes, not much to look at, I’m afraid:

There are thousands of beautiful low-fire glazes that suits well for wood-firing, here are a few of my favorite sites if you want to investigate further:

https://www.lindaarbuckle.com/handouts/lowfire-glaze-recipes.htm#glz0014

https://www.alfredgrindingroom.com/recipes

https://www.priscillahollingsworth.com/uploads/4/9/8/3/4983085/lowfire_glaze_list.pdf

My New Low-Fire Ceramic Glazes

My New Low-Fire Ceramic Glazes – Jan 2025